Coil Nails

SMOOTH SHANK – Coil Nails

Smooth shank nails have no threading and are the easiest to drive. This also makes them the fastest type of nail to drive. Depending on strength and makeup, they can be driven into nearly any surface, and are suitable for a wide range of everyday construction applications—from framing to finishing.

SCREW SHANK – Coil Nails

Screw shank nails combine the benefits of a nail with those of a screw. You get the ease of drive that a nail offers, and approximately the same holding power as that of a screw. The thread forces the nail to turn as it’s driven, essentially forging its own thread in the wood.

RING SHANK – Coil Nails

Ring shank nails have annular (ring-shaped) threads on them that prevent them from being removed as easily as smooth shank nails. When driven, the thread creates a “locking” effect with wood fibers, which gives it greater resistance from withdrawal.

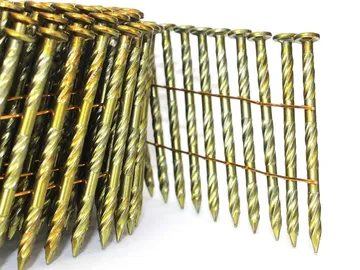

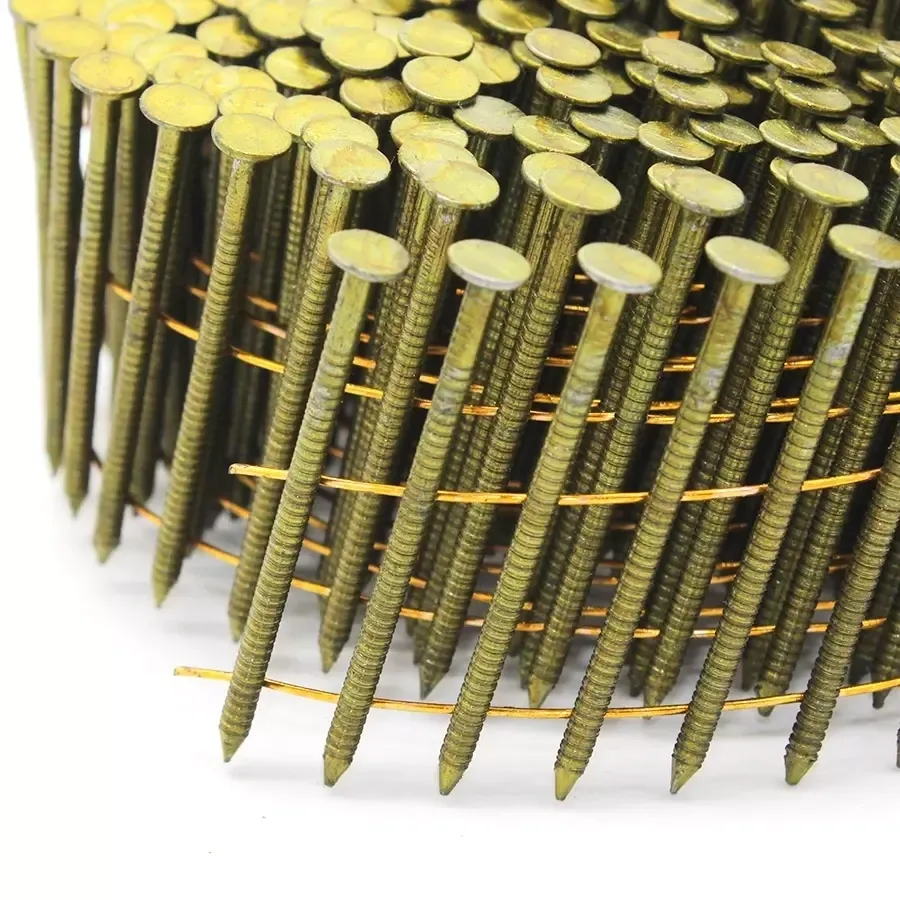

Galvanised Coil Nails

We offer a comprehensive range of Galvanized coil nails, which is designed in compliance with set standards. Our range of pneumatic coil nails is acknowledged for corrosion resistance, smooth finish and durable finish features.

SS Coil Nails

Stainless Steel Coil Nails is non-magnetic and exhibits high resistance to corrosion and oxidation against atmospheric, making it a perfect for wooden packaging in chemical, petroleum, textile, and food industry.

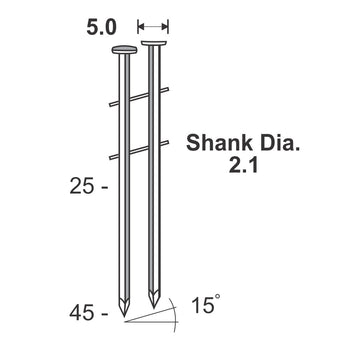

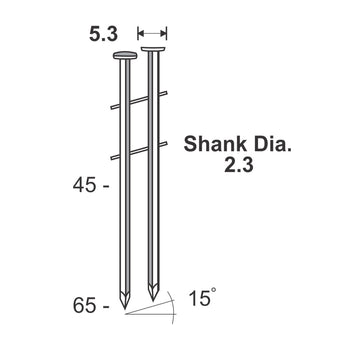

All the COIL NAILS can be availed by our clients in the following technical specifications:

|  |  |  |

|---|---|---|---|

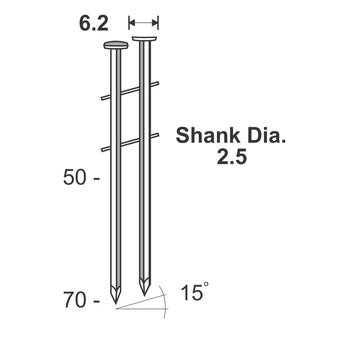

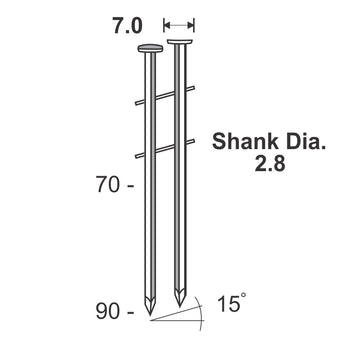

COIL NAILS 2.1 SERIES | COIL NAILS 2.3 SERIES | COIL NAILS 2.5 SERIES | COIL NAILS 2.8 SERIES |

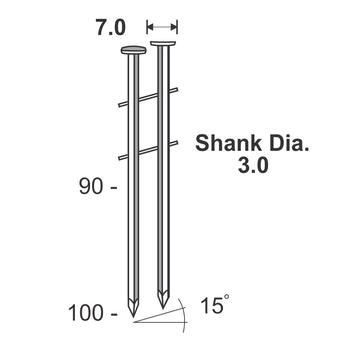

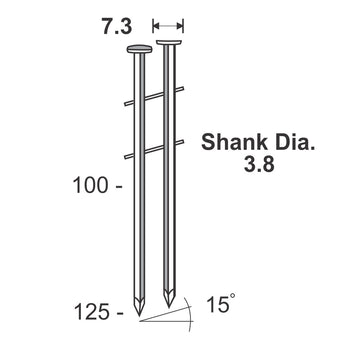

|  | ||

COIL NAILS 3.0 SERIES | COIL NAILS 3.8 SERIES |

STRIP NAILS – 21° Full Head Plastic Strip Nails

Widest range of STRIP NAILS – 21° Full Head Plastic Strip Nails are available with different sizes and shanks.

Common Nails

We are engaged in offering a wide range of wire nails, which is manufactured using high grade basic material. These pointed metal pieces of wire nails are used in most of the manufacturing units and thus fulfill the requirements of varied industry applications. Our clients can avail these at the most competitive prices.

- High tensile strength

- Corrosion resistance

- Fine finish

- Durable finish